Component Introduction

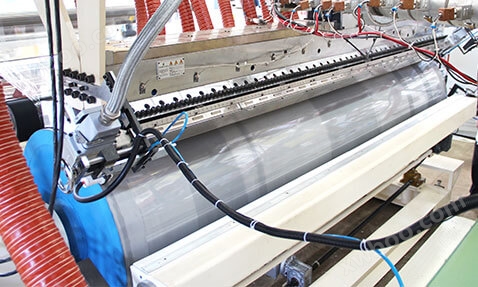

Distributor and mold head

The distributor and automatic flat die system adopt a floating layered plug design, which can be adjusted according to the extrusion volume. Three dimensional melt pipeline, reducing length and avoiding dead corners. By analyzing the melt flow and simulating the process, it is ensured that the T-shaped die has better performance in terms of thickness uniformity cavity design, layer uniformity, and extrusion speed.

Roller temperature control system

The roller temperature control system adopts modular design and can be configured to different production lines according to customer needs, with good universality and adaptability; The temperature control unit adopts independent automatic control for heating and cooling, which has good adaptability to the casting and heat treatment functions, reducing the deformation of the film after winding. Adopting circulating water supply control to save energy consumption and water resource supply.

Casting turret winding

Equipped with a fully automatic turret type winding machine, it integrates central winding and gap winding functions, and has functions such as automatic cutting, automatic coil changing, automatic unloading, and automatic length counting. The unwinding adopts a hydraulic control system, and the tension control adopts a new automatic tension control system with constant tension. It can provide feedback based on the measured surface tension of the film and achieve automatic tracking, improving the flatness of the film winding.